CNC-Fräse: Unterschied zwischen den Versionen

Reox (Diskussion | Beiträge) |

Reox (Diskussion | Beiträge) Keine Bearbeitungszusammenfassung |

||

| Zeile 42: | Zeile 42: | ||

The current machine's state is given by a coordinate triple, and some states (emergency swich, spindle speed, ...). The machine '''coordinate system''' is defined by the now automated homing routine. Thereafter, one can move the machine to a location, and "touch off", giving explicit coordinates for this location. Thereby the working coordinate system is defined. This is also the system displayed in Axis, However, in the background, the machine still works in the home-coordinate system for checking its movement limits. Clever! | The current machine's state is given by a coordinate triple, and some states (emergency swich, spindle speed, ...). The machine '''coordinate system''' is defined by the now automated homing routine. Thereafter, one can move the machine to a location, and "touch off", giving explicit coordinates for this location. Thereby the working coordinate system is defined. This is also the system displayed in Axis, However, in the background, the machine still works in the home-coordinate system for checking its movement limits. Clever! | ||

== Nomenclature == | |||

Or the what is which device: | |||

* CNC PC: a Linux machine running the LinuxCNC Software and sends out commands via Parallel Port | |||

* G4: a old Apple G4 Case holding the stepper drivers | |||

* Stepper Driver: Each stepper driver controls one stepper. There are 5 Stepper Driver in the G4: 2x X, 1x Y, 1x Z, 1x A (currently unused) | |||

* Breakout Board: Is used to "convert" the parallel commands to a different protocol that the stepper drivers are using. Also has a VFD Port to control the Frequenconverter | |||

* FU/Frequenzumrichter/Frequencyconverter: This Box controls the Spindle. It has a output of 100 to 400Hz on 3 Phases and gets controlled by the Breakout Board. | |||

== Standard Procedure == | |||

There are some important steps to take, otherwise you can destroy everything - even the earth... | |||

If you don't switch on the things in this particular order it can happen that the machine does things out of nowhere e.g. moves or turns on the spindle!!! | |||

* Start CNC PC (dont turn on the G4 (The "G4 Case" stepper control thing), neither the FU) | |||

* Start LinuxCNC | |||

* Check if the "Notaus" is physically triggered on the machine (Button is pressed) | |||

* Now power on the G4 | |||

* Now plug in the FU ("Frequenzumformer") | |||

** Wait until the FU is booted | |||

** Check if 100.0 Hz is set on the screen of the FU | |||

*** Otherwise rotate the rotary encoder that it is 100.0Hz | |||

* Now remove "Notaus" from the CNC | |||

* Power on the Machine inside LinuxCNC | |||

* Move near Homing position | |||

* Home the machine | |||

Now the machine is ready to use. | |||

For milling the spindle needs to be warm. The manual says that you should first let the spindle run for about 1 minute on 6000rpm, then increment by 6000rpm for 1 minute until you reached your destination speed. If the spindle wasn't used for longer than one week, you should double that time. | |||

So better is to let it run for two minutes on each speed. | |||

There is a sample code in the Reference Section. | |||

== Current Status== | == Current Status== | ||

Version vom 15. Dezember 2013, 21:04 Uhr

3D-Scanner - CNC-Fräse - Laser - Reflow Oven - 3DPrinter (Prusa XL, Prusa Mk3S, Prusa Mini) - Vinylplotter - Schweißinverter -Tischbohrmaschine - Drehbank - Ultraschallreiniger - Nähmaschinen

| Language: | English |

|---|

For projects results of this machine, please visit http://geilomat.soup.io/

WARNING: The machine-specific information on this page is probably outdated! We have a new spindle, which has very different properties.

Introduction

A CNC mill like the dear Geil-O-Mat has three axis that can be moved independently. A spindle with a mill cutter typically removes material.

Each axis is driven by one (Y and Z) or two (X) stepper motors. Basically, theses motors can only rotate in 1.8 degree steps, and hence no secondary encoder is needed for the machine knowing its current location. By a trick called "microstepping", currently the resolution is increased to 1/8 of 1.8 degrees. As the stepper leads in to a "Zwillings-Trapezgewindespindel", the rotation is transformed into linear motion, one revolution= 6mm. Warning: If there is too much force for the motor to move one step, it skips the step, typically failing also in subsequent movements, resulting in an ugly noise, and shift in the positioning.

The motors are connected to a driver device, which sits on top of the whole machine. It creates the strong currents for the stepper drivers, out of signals from the PCs parallel port.

Hence, the computer has to send signals telling which axis should move one step forward or backward at a given instance. This can/is done by a software called "EMC". It is open source, and the thread doing this parallel port communications is using the patched real time Linux-kernel.

There are some GUIs for EMC, the most relevant is "AXIS", which graphically displays the current machine position, the paths it should travel the track history, and further stuff. Also manual movement can be performed.

The language to specify the movement of the machine is called "GCODE". Some of its statements are starting with G01,or G00, hence the name. A simple Gcode can look like this:

; i am a comment F100; move with 100mm/min while cutting G0 Z10; fast move to Z-coordinate 10 G1 Z0; drill down until Z=0 with the speed given by the Feedrate G1 X10; move to the new location X10 while cutting G0 Z10; and back up with large speed. M30; end program

One can do a lot of things, e.g. have variables (#1=10), and do loops , evaluate mathematical expressions (G1 Z[#1*2] ). So basically, real hackers write gcode by hand, while Chuck Norris sends movement commands to the steppers. However, as we are all lacy, and things can get quite complicated, there exists software to convert 3d/2d CAD files, grayscale depthmap images, 3d-stl objects and other things into Gode. This is often called "CAM"-Software.

If you have a 2d-cad file (e.g. dxf) and specify depths for some areas that should be milled away, one speaks of 2.5D-CAM. This is performed e.g. by CamBam, or Camexpert.

The biggest trouble is the radius compensation of the milling heads. You always have to cut on a path half a diameter outside of the actual position. For this, there are various workflows. In Gcode, one can tell specify if one wants to cut left, right or directly on the actual path. This is called cutter radius compensations. Its a pain in the ass. Hence, often one uses no such thing, but either draws directly the offsetted lines in CAD, or has some software like cambam, which does this compensation and outputs already compensated "paths". The drawback of both methods is that one can not change the diameter of the cutter without recreating the gcode.

In the Gcode compensation, a "tool table" is used. Each cutter is index by a number, and in the table the diameters and other things are specified.

The current machine's state is given by a coordinate triple, and some states (emergency swich, spindle speed, ...). The machine coordinate system is defined by the now automated homing routine. Thereafter, one can move the machine to a location, and "touch off", giving explicit coordinates for this location. Thereby the working coordinate system is defined. This is also the system displayed in Axis, However, in the background, the machine still works in the home-coordinate system for checking its movement limits. Clever!

Nomenclature

Or the what is which device:

- CNC PC: a Linux machine running the LinuxCNC Software and sends out commands via Parallel Port

- G4: a old Apple G4 Case holding the stepper drivers

- Stepper Driver: Each stepper driver controls one stepper. There are 5 Stepper Driver in the G4: 2x X, 1x Y, 1x Z, 1x A (currently unused)

- Breakout Board: Is used to "convert" the parallel commands to a different protocol that the stepper drivers are using. Also has a VFD Port to control the Frequenconverter

- FU/Frequenzumrichter/Frequencyconverter: This Box controls the Spindle. It has a output of 100 to 400Hz on 3 Phases and gets controlled by the Breakout Board.

Standard Procedure

There are some important steps to take, otherwise you can destroy everything - even the earth... If you don't switch on the things in this particular order it can happen that the machine does things out of nowhere e.g. moves or turns on the spindle!!!

- Start CNC PC (dont turn on the G4 (The "G4 Case" stepper control thing), neither the FU)

- Start LinuxCNC

- Check if the "Notaus" is physically triggered on the machine (Button is pressed)

- Now power on the G4

- Now plug in the FU ("Frequenzumformer")

- Wait until the FU is booted

- Check if 100.0 Hz is set on the screen of the FU

- Otherwise rotate the rotary encoder that it is 100.0Hz

- Now remove "Notaus" from the CNC

- Power on the Machine inside LinuxCNC

- Move near Homing position

- Home the machine

Now the machine is ready to use.

For milling the spindle needs to be warm. The manual says that you should first let the spindle run for about 1 minute on 6000rpm, then increment by 6000rpm for 1 minute until you reached your destination speed. If the spindle wasn't used for longer than one week, you should double that time. So better is to let it run for two minutes on each speed.

There is a sample code in the Reference Section.

Current Status

- EMC is quite configured. Max-Movement speed is approx 1980 mm/min.

- Consider not drive this fast anyway - 2200mm/min is currently a good setup without loosing steps

- If you use feed-override, please make sure not to run with 1980*1,5mm/min!

- Homeing procedure in EMC is functional, and by that also soft-limits. Its now "nearly" impossible to move over some limits. Start EMC, turn machine on with f1/f2, press "home all", wait 30 sec. Than traverse to the wished zero of your working coordinate system, and touch off in all three axes.

- The Spindle, aka the Mechatron, is switched on/off automatically.

- Spindle speed must be set to a value between 6000 and 24000. Use GCode like M3 S6000

- The Spindle needs some warmup before running. Manual says One minute on 6000rpm, then increase in steps of 6000 until the whished speed is reached. stay for one minute on each level. If the spindle is very cold and has not run about a week double the times!

- Double sided boards kind of work, although its a bit tricky: PCB_CNC

Todo

- http://softsolder.com/2010/04/17/ugliest-tool-length-probe-switch-repeatability/

- get some flat 4-5 mm wood to put underneath the actual workpeace for cutting/milling through.

- Revitalize the "Absaugung"

- Reboot the lubrication thingy.

- It works by turning on the compressor. The Hex-Screw changes the ammount, the ball-stick turns it on/off.

- Find a way of dealing with oily aluminium dust.

- buy some normal wood in reasonable size (40x100x1.8 cm)

- organize some aluminium for testing

Ideas

- build/buy a touch-probe (or like this).

- Build/buy a Vakuum-Table

- A led-ring for illumination the milling location.

- Build a 4th, rotating axis.

--Bkubicek 13:44, 4. Jun. 2010 (CEST)

Wishlist

- too much ;)

History

Es war einmal .. eine CNCfräse.

Sie war eine gute Fräse und alle Kinder hatten sie gerne, spielten mit ihr und tanzten im bunten Reigen singend um sie herum..

Doch eines Tages rief sie das Schicksal und sie musste ihrer Bestimmung nachkommen .. dem Fräsen.

Nicht dass du glaubst sie wäre darin nicht gut gewesen.

Nein nein! Ganz im Gegenteil!!

Sie war eine ausgezeichnete Fräse!

..aber die Materialien staubten ganz fürchterlich und der Lärm brachte die verkaterten Schädel der Kinder zum Zittern..

Die Fräse schien verflucht!

Soviel Gutes und Schönes sie auch in der Welt zu bewirken vermochte, soviel Schrecken und Dreck verursachten der Staub und Lärm sobald man ihren Motor anwarf.

Eines Tages erfuhr ein edler Ritter von diesem Dilemma und machte sich auf den Weg, die verwunschene Maschine von ihren Leiden zu erlösen.

Er schwang sich auf sein weißes Ross, schwer behangen mit

- einem Akkubohrer

- einer Stichsäge

- 3 Plexiglasplatten

- 5 Pressspanplatten

- 2 Scharnieren

- 4 Magnetkontakten

- 2 Türgriffen

- unendlich vielen Winkeln

- einem Staubsauger

- einer Neonröhre mit Schutzglas

.. und bezwang in einer spektakulären zweitägigen Heimwerkeraktion das Biest.

Heute lebt die Fräse im Metalabber Whateverlab, hat eine integrierte Staubabsaugung, Schalldämmung und Beleuchtung.

Ihr bester Freund der Computer hat eine umfangreiche Palette an CNC Software installiert und ist fix mit dem Biest verbunden..

Und wenn sie nicht gestorben sind dann fräsen sie noch heute.

..und warum jetzt geil-o-mat?

weil ich das gut finde.

--Overflo 13:56, 8. Dez. 2007 (CET)

The big reconfiguration

between 2012 and now some crazy guys had a vision in their heads that the CNC needs to be reconfigured. They build a heavy (around 700kg) table and cage and pimped the settings of the cnc. they even installed a HF Spindle for super mega awesome milling.

Reference

a usefull preamble for this mill:

M3 ; starts spindl clockwise (looking from above down) S6000 ; 6000 min-1 G4 P60 ; wait for 60 seconds S12000 ; 12000 min-1 until the whished speed is reached G4 P60 F950 ; xyz feedrate 950 mm/min G90 G21

Cheat Sheat

Ersetzen Gcode-Zeilennummern im Texteditor Kate replace "N[0-9]* " by "" using regular expression.

Example Gcode Header for Geilomat:

G21 ; mm G90 ; absolute coordinates G0 Z10 G0 X0 Y0 F500 ; 500mm/minutes movement speed M7 ; staubsauger an M3 ; fraeser einschalten S6000 ; Drehzahl auf 6000 min-1 einstellen G4 P120 ; 2min warten bis motor warm ist S12000 ; Drehzahl erhöhen G4 P60 ; 1min warten. (immer um 6000 erhöhen bis die Drehzahl erreicht wurde)

Typical gcode Tail:

; the tail G0 Z10 ; retract from workplane - safty plane M30 ; end program

Parameters for typical jobs

| Material | Head Diameter mm | Cutting Depth mm | Sidewards depth in % of diameter | Spindle Speed | Feed Rate mm/min | Comment |

|---|---|---|---|---|---|---|

| MDF | 8 | 2 | ? | 12000 | 30 | MDF is usually too thick to be milled with our normal milling heads, so we're using a bigger (8mm diameter) end mill. Plunge 10. |

| Wood | 3 | 5 | 50% | 12000-14000 | >300 | guessed proposal |

| Wood | 0.8 | 4 | 100% | 12000-14000 | ~250 | guessed proposal |

| Aluminium | 3 | 1 | 50% | 6000 | 300 | guessed proposal with cooling |

| Aluminium | 10 | 10 | 20% | 7990 | 3000 | on an industrial machine, for comparison |

| PCB engrave | 0.1-0.3 30deg | 0.3 | 12000 | 1000 | tested in epoxy-pcb | |

| PCB drill | 0.9 | -2.5 | 14000 | 400 | tested in epoxy-pcb | |

| Plexiglass Front door engrave | 0.1 30deg? | 1 | 10000 | 20 | Plunge 20, toolsize cambam 0.3 | |

| Plexiglass egg | 1.5 30deg? | 0.5 | 14000 | 100 | Plunge 30, toolsize cambam 1.5 : 4mm thick plexiglass 400x300 | |

| Plexiglas Portrait | 0.1 30deg? | 4 | 10000 | ? | 0.3mm raster, Custom tool to convert from image to gcode |

Warning: Do not use a too low feed-rate!! The cutting region of the milling head is microscopically round. If the "Spanbreite", the thickness of the removed material, is lower that this radius, most material is compressed and only cut if the compression force is to large. This results in dramatic friction and hence only heats up the milling head. The thought "Oh, the cutter is getting too hot, I can see burning marks in the side of the wood, I have to reduce the movement speed" is deadly!!! You can decrease the spindle speed, and increase the movement speed.

The Heat produced while cutting depends on the friction. A second part is proportional to the volume of material that is removed. Half the milling depth, half the heating! 25% sidewards instead of 50% sidewards cutting=half the heating. Mill heads can break if the sidewards force is too large. So for tiny things, the feed rate together with the spindle speed and the cutting depth should be reduced.

Pocketing plexiglass:

- Choose engraving bit according to pocket size.

- Be careful with CutIncrement (1mm is ok).

- Be aware that plexiglass melts, so it's important to use cooling.

- For bigger pocket operations, the vacuum cleaner has a certain cooling effect.

- Air pressure and water cooling was necessary for the front door window engraving.

Cutting GFK (glasfaserverstärkter Kunststoff):

(Acquirable at http://www.der-schweighofer.at/artikel/77271/gfk_platte_300x135x1.5mm)

The following values work fine for cutting 1,5mm thick GFK.

- Plunge Feed-rate: 100

- Cut Feed-rate: 1500

- Depth Increment: 0,8mm

- Feed override: 75%

How to

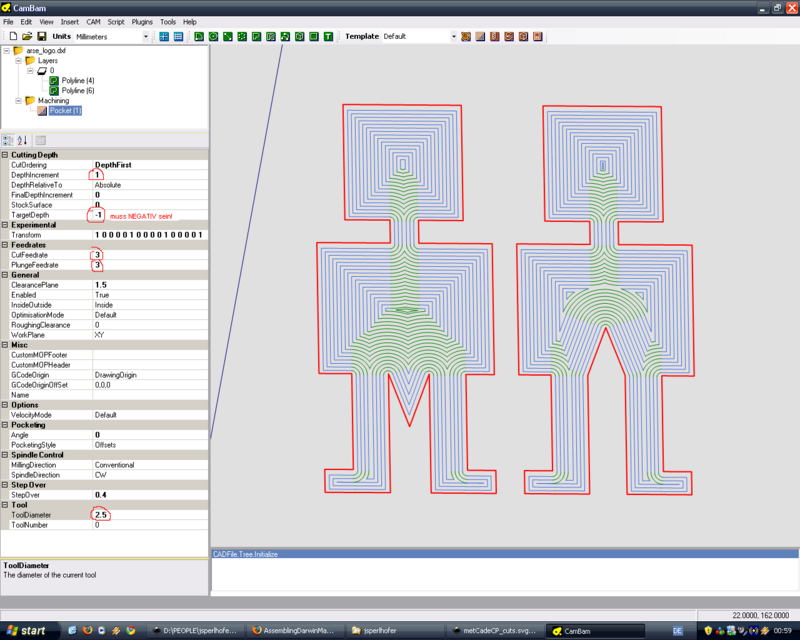

CamBam Mini HowTo

Sehr wichtige Parameter

- CutIncrement - Wie tief geht die fraese in einem schritt

- TargetDepth - Wie tief soll er insgesammt gehen. Die operation wird dann in TargetDepth/cutIncrement unterschritte zerlegt. ACHTUNG dieser wert muss negativ sein damit die fraese rein fraest.

- CutFeedrate Wie schnell wird horizontal gefraest (mm/sec)

- PlungeFeedrate Wie schnell wird in das Material hineingetaucht (mm/sec)

- ToolDiameter Durchmesser des Fraeskopfes damit CamBam die pfade so berechnen kann dass nach dem fraesen die gewuenschte form entsteht

Weitere Parameter

- InsideOutside Falls man die Outline verkehrt herum geyeichnet hat kann man mit dieser option innen und aussen umdrehen (einfach mal ausprobieren)

Drilling and cutting PCB's (epoxy)

Cutting and drilling Aluminium

Needs cooling. No success yet. Our spindle might be too fast for drilling.

Meh, it should work fine.

Toolchain

CamBam

CamBam is at the moment the tool of choice for defining operations, tool path generation and gcode export. To a certain degree, it's also possible to use CamBam for design as well.

Note! CamBam is neither Free Software or freeware, but commercial software with a 40-time use evaluation license.

CamBam can import DXF.

Camexpert

Having a dxf done with all the cutting paths, camexpert can export gcode. Manual editing of the gocde is although necessary. Learning curve is not as steep as with cambam.

Design Tools

- Inkscape: Produces SVG and has export options for EPS and DXF.

- Adobe Illustrator: .ai files can usually be read by Postscript/PDF software and be exported as EPS.

- OmniGraffle: Can export EPS

- Mentor Graphics:

- Eagle:

- QCAD

Fileformats -> CamBam

- SVG: Inkscape

- EPS: pstoedit -f dxf <infile.eps> <outfile.dxf> (http://www.pstoedit.net/pstoedit)

Verwandte Seiten

CNC - Software Infos und so..

Formeln zum Berechnen von Zustellung, Umdrehungsgeschwindigkeit usw.

Was Sie über Werkzeuge wissen sollten Wikipedia Onlineberechnungen

Falls sich jemand mit der Anwendung der Formeln auskennt bitte melden. Weiters gesucht das Buch "Der Werkstatthelfer".

Debugging Checklist

- Damit die Limit Switches funktionieren, muss der Druckerport im BIOS auf ECC+EPP gestellt sein. Ansonsten sind die Relevanten Eingangs-Pins kommentarlos nicht einlesbar.

- Wenn man Limits in EMC ausgelöst hat, hilft ein "override limits häckchen", ein einschalten (F1/F2), und ein wegfahren in die entsprechende richtung (Cursortasten und Page up/down)

- Wenn man die Fräse einrichten muss, sind wichtige Hinweise hier gesammelt: Benutzer:Reox/CNC --Reox 18:10, 4. Jul. 2013 (CEST)

CNC PC

On the CNC PC runs a Ubuntu version with a realtime kernel and 2.6 LinuxCNC. Because the dependecies for linuxcnc are really messed up, please do not try to update the PC! --Reox 14:36, 31. Aug. 2013 (CEST)

- The PC has a Backup Harddisk, which contains a complete working system image for system restore.

- The linuxcnc config folder (/home/cnc/linuxcnc/config) is a git repo, so please commit your changes if you changed something on the config.

- Better: If you want to try new settings copy the Geilomat config and create your own - the Geilomat setup should be sufficant for everyone, so you need good reason to change it

- The PC has APIC disabled, because of realtime kernel jitter reasons. so if you power it down, you need to press the power button after the system says "system halted"

Syntax Highlighting in Kate/Kwrite

in "~/.kde/share/apps/katepart/syntax" put Datei:Gcode.xml.txt without the txt extension.