Salami Rocket: Unterschied zwischen den Versionen

Amir (Diskussion | Beiträge) K (→Parts) |

Amir (Diskussion | Beiträge) K (→Parts) |

||

| Zeile 17: | Zeile 17: | ||

= Parts = | = Parts = | ||

[[Bild:Scaled-dscn9121.jpg|thumb|Overview of the rocket parts]] | [[Bild:Scaled-dscn9121.jpg|thumb|Overview of the rocket parts]] | ||

| − | All parts directly participating in the combustion would have to sustain at least 51 bar | + | All parts directly participating in the combustion would have to sustain at least 51 bar<br>(vapor pressure of N<sub>2</sub>0 at 20°C) but for reasons of safety i assume 200bar as the minimum. |

| − | (vapor pressure of N<sub>2</sub>0 at 20°C) but for reasons of safety i assume 200bar as the minimum. | ||

* [http://en.wikipedia.org/wiki/Pressure_vessel Run Tank]: A light-weight container for the oxydizer capable of sustaining enough pressure | * [http://en.wikipedia.org/wiki/Pressure_vessel Run Tank]: A light-weight container for the oxydizer capable of sustaining enough pressure | ||

Version vom 30. Juli 2009, 03:53 Uhr

WTF?

Nomen est omen. Salami rocket is about building a hybrid rocket with a gaseous oxydizer (N20) and salami as propellants.

Oxydizer

I chose N2O over O2 because although N2O carries a lot of conjectural inert nitrogen (64%) oxygen is much harder to handle (tank filling, storage & injection). Additionally the nitrogen, though not participating in combustion, raises the fuel erosion rate and cooles the nozzle enough to reuse it many times. Since the alternatives i found are quite expensive, i use the nitrous oxyde of whipped-cream chargers. By the way, never search for "Sahnespender" at google.

Fuel

Salami: High efficency hydrocarbon based fuel ;)

Simulation

Im using RockSim to simulate the flight stability of the rocket. The behaviour of the N20/ hybrid motor is simulated by an external model programmed in C++.

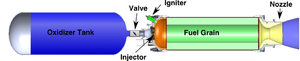

Parts

All parts directly participating in the combustion would have to sustain at least 51 bar

(vapor pressure of N20 at 20°C) but for reasons of safety i assume 200bar as the minimum.

- Run Tank: A light-weight container for the oxydizer capable of sustaining enough pressure

- Throttle Valve: A valve to allow precise regulation of the oxydizer flow from the run tank to the combustion chamber.

- Injector: Aids in vaporizing the (still) liquid oxydizery.

- Combustion Chamber: Where the oxydizer/fuel mix burns. Additionally to pressure (same amount as for the run tank) it has to sustain heat.

- Nozzle: An opening that dramatically accelerates the hot gas escaping the combustion chamber.

- Ignitor: Preheating the fuel and initializing combustion.

- Body tube: Enhances airodynamic properties of the rocket and encapsulates the motor.

- Motor mount: Anchors the motor within the body tube

- Fins: Enhances airodynamic/stability properties of the rocket.

- Recovery System (parachute): Enables slow decent after burn-out for safety and reusability

- Tail camera: It's all about the nice view

- Altimeter: Measurement concludes the fate of the cat

- Electric beacon: Transmits a signal to ease finding the landing site.

- Filling system: Pipework to fill the run tank with nitrous oxyde from whipped cream chargers.

Run Tank

Smart Parts C02 aluminium tank for paintball guns with on/off valve.

- Capacity: 591ml (20 oz)

- Connector: 1,27cm (1/2")

- Max Pressure: 200bar

Throttle valve

An adjustable throttle valve ([1]) intended for use in hydraulics.

- Connector: 1,27cm (1/2")

- Flow rate: 45 l/min

- Working pressure: 350 bar

Injector

- Diameter: 54mm

Combustion Chamber

C02 aluminium tank for paintball guns without on/off valve.

- Capacity: 255ml (9 oz)

- Connector: 1,27cm (1/2")

- Max Pressure: 200bar

Nozzle

SKR-54NZL graphite nozzle

- Diameter: 54mm

Ignitor

None selected yet.

Body tube

Cardboard tube, intended for postal delivery.

- Dimension: 1000 x 140 x 3 mm

Motor mount & Fins

Wooden centering rings and perspex fins, precisely milled with a CNC machine.

Recover System

None specified/selected yet.

Testing

After a few backyard tests with a rather improvised device, we tested the actual motor at Lindabrunn. Special thanks to kyrah and marius for support, pyromantic inspiration and fuel sponsoring.

- Bazooka

- Bazooka - alternate version

- Smoked Salami

- Almost Burning

- Almost Burning - alternate version

- Burn!

Links

- Basic concept of hybrid rockets at wikipedia

- Excellent tech papers on calculating, planing and building hybrid rockets

- Very helpful articles of Richard Nakka about his experimental rockets

- Rocketry know-how DB (DE)

- Model Rocketry Tips

- Building a Model Rocket Parachute Recovery System by Dr. Jean Potvin

- Nasa: Rocket thrust Equations