Salami Rocket

WTF?

Nomen est omen. Salami rocket is about building a hybrid rocket with a gaseous oxydizer (N20) and salami as propellants.

Oxydizer

I'd prefer N2O over O2 because although N2O carries a lot of conjectural inert nitrogen (64%) oxygen is much harder to handle (tank filling, storage & injection). Additionally the nitrogen, though not participating in combustion, raises the fuel erosion rate and cooles the nozzle enough to reuse it many times. Most likely, since the alternatives i found are quite expensive, i will use the nitrous oxyde of whipped-cream chargers. By the way, never search for "Sahnespender" at google.

Fuel

Salami: High efficency hydrocarbon based fuel ;)

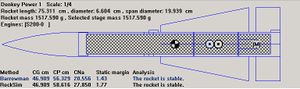

Simulation

Im using RockSim to simulate the flight stability of the rocket. The behaviour of the N20/Salami hybrid motor is simulated by an external model programmed in C++.

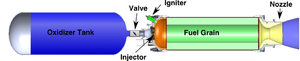

Draft

- Run Tank: A light-weight container for the oxydizer capable of sustaining enough pressure

- On/Off Valve: Enables/Disables oxydizer flow.

- Throttle Valve: A valve to allow precise regulation of the oxydizer flow from the run tank to the combustion chamber.

- Injector: Aids in vaporizing the (still) liquid oxydizery.

- Combustion Chamber: Where the oxydizer/fuel mix burns. Additionally to pressure (same amount as for the run tank) it has to sustain heat.

- Nozzle: An opening that dramatically accelerates the hot gas escaping the combustion chamber.

- Ignitor: Preheating the fuel and initializing combustion.

- Shell: Protecting the motor

- Recovery System (parachute): Enables slow decent after burn-out for safety and reusability

- Tail camera: It's all about the nice view

- Altimeter: Measurement concludes the fate of the cat

- Electric beacon: Transmits a signal to ease finding the landing site.

- Filling system: Pipework to fill the run tank with nitrous oxyde from whipped cream chargers.

Shopping list

All parts directly participating in the combustion would have to sustain at least 51 bar (vapor pressure of N20 at 20°C) but for reasons of safety i assume 200bar as the minimum.

Run Tank

Smart Parts C02 aluminium tank for paintball guns with on/off valve.

- Capacity: 591ml (20 oz)

- Connector: 1,27cm (1/2")

- Max Pressure: 200bar

- Price: 45€

On/Off Valve

No separate valve needed since the proposed CO2 tank has it built-in.

Throttle valve

An adjustable throttle valve (Stasto VRB-030) intended for use in hydraulics.

- Connector: 1,27cm (1/2")

- Flow rate: 45 l/min

- Working pressure: 350 bar

- Price: 30€

Injector

Probably custom made or this one -> SKR-54UC

- Diameter: 54mm

- Price: 53 €

Combustion Chamber

C02 aluminium tank for paintball guns without on/off valve.

- Capacity: 591ml (20 oz)

- Connector: 1,27cm (1/2")

- Max Pressure: 200bar

- Price: 14€

Nozzle

SKR-54NZL graphite nozzle

- Diameter: 54mm

- Price: €35

Ignitor

None selected yet.

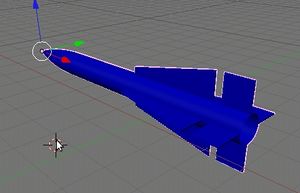

Shell

A nice design proposal by mactux. Exact specifications & blue prints yet to be made.

Recover System

None specified/selected yet.