Archiv:RepRap: Unterschied zwischen den Versionen

Pk (Diskussion | Beiträge) K +kat. |

Pk (Diskussion | Beiträge) →WTF?: upd |

||

| Zeile 1: | Zeile 1: | ||

=== WTF? === | === WTF? === | ||

This project is about building a 3D printer for rapid prototyping. In contrast to a milling machine the process is additive i.e. the workpiece is built-up layer by layer, usually from thermoplastic material. | This project is about building a '''3D printer for rapid prototyping'''. In contrast to a milling machine the process is additive i.e. the workpiece is built-up layer by layer, usually from thermoplastic material. Different commercial devices exists - needless to say, they are pricey. The goal of a RepRap machine is the ability to print almost all parts it consists of, hence ''a self-'''rep'''licating '''rap'''id prototyper''. | ||

{|width="100%" | {|width="100%" | ||

| | | | ||

After seing [[RepRap Workshop|Vik's presentation]] about [http://reprapdoc.voodoo.co.nz/bin/view/Main/HowToBuildOne how to build a RepRap] we've started our own implementation of a [http://www.reprap.org RepRap]. | After seing [[RepRap Workshop|Vik's presentation]] about [http://reprapdoc.voodoo.co.nz/bin/view/Main/HowToBuildOne how to build a RepRap] we've started our own implementation of a [http://www.reprap.org RepRap]. | ||

Then [http://brepettis.com Bre Pettis] came by in November 2007 and decided to build a [http://reprap.org/bin/view/Main/McWire_Cartesian_Bot_1_2 McWire]-based RepRap for [http://www.roboexotica.org Roboexotica]. In a week. | Then [http://brepettis.com Bre Pettis] came by in November 2007 and decided to build a [http://reprap.org/bin/view/Main/McWire_Cartesian_Bot_1_2 McWire]-based RepRap for [http://www.roboexotica.org Roboexotica 2007]. In a week. Unfortunately the motor drivers have been blown during exhibition but the revived machine has been sucessfully presented at [http://hackaday.com/2008/12/05/roboexotica-2008/ Robexotica 2008], it even won an [http://flickr.com/photos/ctp/3095372499/ award]. | ||

Metalab inherited [http://blog.makezine.com/archive/2007/11/make_a_reprap_robot_part_1.html Bre's RepRap] (yay!) and it's now used as a basis for our own RepRap. | Metalab inherited [http://blog.makezine.com/archive/2007/11/make_a_reprap_robot_part_1.html Bre's RepRap] (yay!) and it's now used as a basis for our own RepRap. | ||

Version vom 24. Dezember 2008, 08:09 Uhr

WTF?

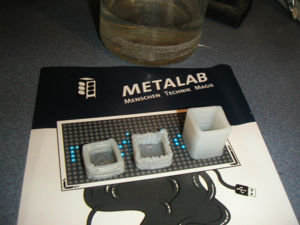

This project is about building a 3D printer for rapid prototyping. In contrast to a milling machine the process is additive i.e. the workpiece is built-up layer by layer, usually from thermoplastic material. Different commercial devices exists - needless to say, they are pricey. The goal of a RepRap machine is the ability to print almost all parts it consists of, hence a self-replicating rapid prototyper.

|

After seing Vik's presentation about how to build a RepRap we've started our own implementation of a RepRap. Then Bre Pettis came by in November 2007 and decided to build a McWire-based RepRap for Roboexotica 2007. In a week. Unfortunately the motor drivers have been blown during exhibition but the revived machine has been sucessfully presented at Robexotica 2008, it even won an award. Metalab inherited Bre's RepRap (yay!) and it's now used as a basis for our own RepRap. Note: At the moment, what we're building is really a RepStrap which we already use to print parts for our first "real" RepRap. Status (List of Milestones achieved )Recent progress can be seen at the Metalab RepRap Soup

Next Steps

Materials in the Lab

Links

PicturesMost recent entries from http://reprap.soup.io<websiteFrame> website=http://reprap.soup.io/mini/400/7/ height=800 width=90% border=1 scroll=yes </websiteFrame>

Sponsored by Wien Kultur (MA7) |