Archiv:RepRap: Unterschied zwischen den Versionen

(update) |

Pk (Diskussion | Beiträge) (what is is all about, img layout, category) |

||

| Zeile 1: | Zeile 1: | ||

=== WTF? === | === WTF? === | ||

| + | This project is about building a 3D printer for rapid prototyping. In contrast to a milling machine the process is additive i.e. the workpiece is built-up layer by layer, usually from thermoplastic material. Some commercial devices exists - needless to say, they are pricey. The goal of a RepRap machine is the ability to print almost all parts it consists of, hence ''a self-'''rep'''licating '''rap'''id prototyper''. | ||

| + | {|width="100%" | ||

| + | | | ||

After seing [[RepRap Workshop|Vik's presentation]] about [http://reprapdoc.voodoo.co.nz/bin/view/Main/HowToBuildOne how to build a RepRap] we've started our own implementation of a [http://www.reprap.org RepRap]. | After seing [[RepRap Workshop|Vik's presentation]] about [http://reprapdoc.voodoo.co.nz/bin/view/Main/HowToBuildOne how to build a RepRap] we've started our own implementation of a [http://www.reprap.org RepRap]. | ||

Then [http://brepettis.com Bre Pettis] came by in November 2007 and decided to build a [http://reprap.org/bin/view/Main/McWire_Cartesian_Bot_1_2 McWire]-based RepRap for [http://www.roboexotica.org Roboexotica]. In a week. | Then [http://brepettis.com Bre Pettis] came by in November 2007 and decided to build a [http://reprap.org/bin/view/Main/McWire_Cartesian_Bot_1_2 McWire]-based RepRap for [http://www.roboexotica.org Roboexotica]. In a week. | ||

Metalab inherited [http://blog.makezine.com/archive/2007/11/make_a_reprap_robot_part_1.html Bre's RepRap] (yay!) and it's now used as a basis for our own RepRap. | Metalab inherited [http://blog.makezine.com/archive/2007/11/make_a_reprap_robot_part_1.html Bre's RepRap] (yay!) and it's now used as a basis for our own RepRap. | ||

| − | |||

| − | |||

| − | |||

| − | |||

Note: At the moment, what we're building is really a [http://reprap.org/bin/view/Main/RepStrap RepStrap]. | Note: At the moment, what we're building is really a [http://reprap.org/bin/view/Main/RepStrap RepStrap]. | ||

| Zeile 16: | Zeile 15: | ||

* We can now also control our CNC machine from the RepRap software using a modified Arduino firmware and a CNC Arduino shield. | * We can now also control our CNC machine from the RepRap software using a modified Arduino firmware and a CNC Arduino shield. | ||

* First version of the extruder is resurrected from Bre's old parts and successfully extrudes [http://en.wikipedia.org/wiki/Hdpe HDPE]. | * First version of the extruder is resurrected from Bre's old parts and successfully extrudes [http://en.wikipedia.org/wiki/Hdpe HDPE]. | ||

| − | * We can print handcoded objects using a quick and dirty | + | * We can print handcoded objects using a quick and dirty Arduino firmware. |

* Next step is to test a complete run from design to printed part. A lot of stuff will go wrong here, and the TODO list will depend on the outcome, but more work on the extruder is needed. | * Next step is to test a complete run from design to printed part. A lot of stuff will go wrong here, and the TODO list will depend on the outcome, but more work on the extruder is needed. | ||

| Zeile 28: | Zeile 27: | ||

* [http://reprappers.blogspot.com/ RepRap Builder Blog] | * [http://reprappers.blogspot.com/ RepRap Builder Blog] | ||

* [http://reprap.blogspot.com/ RepRap Project Blog] | * [http://reprap.blogspot.com/ RepRap Project Blog] | ||

| − | + | | | |

| + | {| | ||

| + | | [[Bild:reprap.jpg|300px|right]] | ||

| + | |- | ||

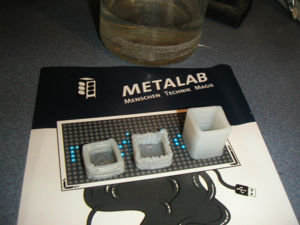

| + | | [[Bild:Metalab reprap print.jpg|300px|right]] | ||

| + | |- | ||

| + | | [[Bild:Metalab reprap firstparts.jpg|300px|right]] | ||

| + | |} | ||

| + | |} | ||

__NOTOC__ | __NOTOC__ | ||

| + | [[Kategorie:Projekte]] | ||

| + | [[Kategorie:WhateverLab]] | ||

| + | [[Kategorie:English]] | ||

Version vom 20. Juni 2008, 14:49 Uhr

WTF?

This project is about building a 3D printer for rapid prototyping. In contrast to a milling machine the process is additive i.e. the workpiece is built-up layer by layer, usually from thermoplastic material. Some commercial devices exists - needless to say, they are pricey. The goal of a RepRap machine is the ability to print almost all parts it consists of, hence a self-replicating rapid prototyper.

|

After seing Vik's presentation about how to build a RepRap we've started our own implementation of a RepRap. Then Bre Pettis came by in November 2007 and decided to build a McWire-based RepRap for Roboexotica. In a week. Metalab inherited Bre's RepRap (yay!) and it's now used as a basis for our own RepRap. Note: At the moment, what we're building is really a RepStrap. Status

Materials in the Lab

Links |

|