CNC-Fräse/Technical: Unterschied zwischen den Versionen

Reox (Diskussion | Beiträge) Keine Bearbeitungszusammenfassung |

Reox (Diskussion | Beiträge) Keine Bearbeitungszusammenfassung |

||

| Zeile 6: | Zeile 6: | ||

In our current setup we use Sanyo Denki 103h7126-0740 Motors, which are linear until about 1000 to 2000 pulses/second. We are using 8 Microsteps, so the normal 200 steps per revolution (1.8 Degree step size) must be multiplied by 8, which gives 1600 steps per revolution. | In our current setup we use Sanyo Denki 103h7126-0740 Motors, which are linear until about 1000 to 2000 pulses/second. We are using 8 Microsteps, so the normal 200 steps per revolution (1.8 Degree step size) must be multiplied by 8, which gives 1600 steps per revolution. | ||

Now we can calculate the maximum speed for a axis by taking the maximum pulses/second and divide it by the steps needed per mm (266,6 on our machine): | Now we can calculate the maximum speed for a axis by taking the maximum pulses/second and divide it by the steps needed per mm (266,6 on our machine): | ||

<math>2000 pulses | <math>\frac{2000 \frac{\text{pulses}}{\text{s}} \cdot 8 \frac{\text{pulses}}{\text{step}}}{266 \frac{\text{steps}}{\text{mm}}} = 60 \frac{\text{mm}}{\text{s}} = 3600 \frac{\text{mm}}{\text{min}}</math> | ||

We need the factor 8 here because of the microstepping. | We need the factor 8 here because of the microstepping. | ||

Version vom 19. Januar 2015, 15:25 Uhr

This page descibes technical aspects of the CNC machine in more detail.

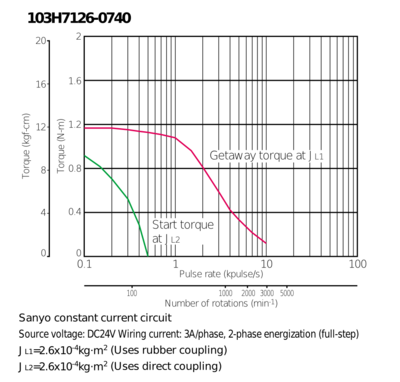

Stepper Torque

The torque of a stepper driver is not linear over the number of revolutions per second. It is nearly linear in the beginning but drops down at a specific point for each motor until it reaches zero. In our current setup we use Sanyo Denki 103h7126-0740 Motors, which are linear until about 1000 to 2000 pulses/second. We are using 8 Microsteps, so the normal 200 steps per revolution (1.8 Degree step size) must be multiplied by 8, which gives 1600 steps per revolution. Now we can calculate the maximum speed for a axis by taking the maximum pulses/second and divide it by the steps needed per mm (266,6 on our machine): We need the factor 8 here because of the microstepping.

This aspect of a stepper motor means also: lower microstep setting allows higher speed and vice versa.